3D Food Printing Experience

Bringing the innovation into the kitchen: Print "as easy as Pie"

I was invited by Lynette Kucsma (Co-Founder & CMO) and by Armando Garcia-Mendoza (Engineering Lead) to collaborate with Natural Machine's development team in order to create a user friendlier experience for Foodini. Such a cutting edge and innovative project demanded a accurate balance between a futuristic vision, and a modern, but current use of interactions and interfaces.

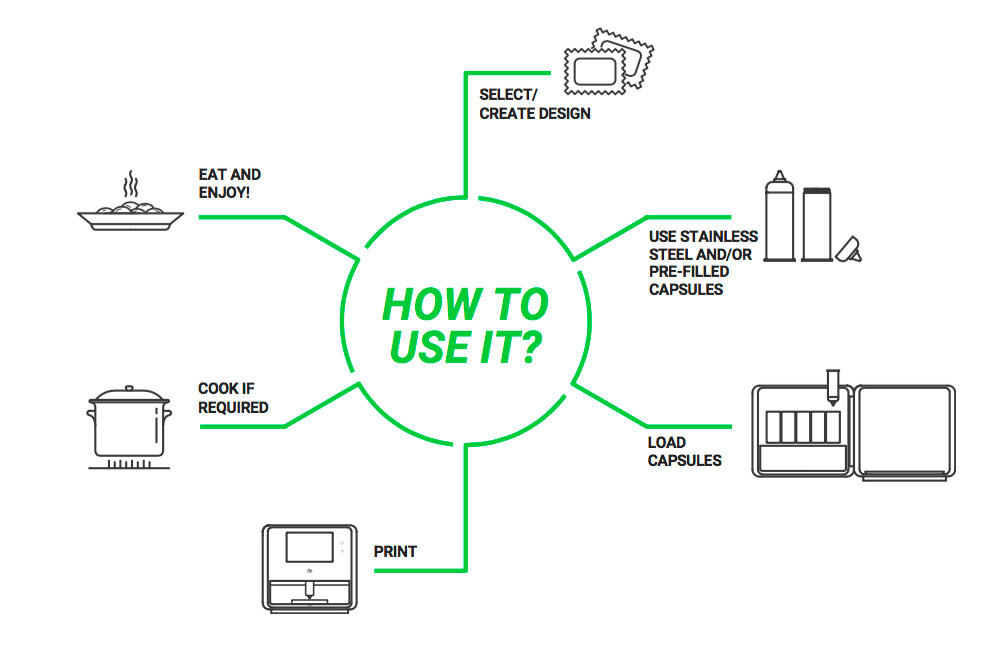

What is Foodini?

It is a 3D printer that combines technology, food, art and design.

Foodini is a very clean system that pushes food down the capsule, through the nozzle, and prints it. A precision control system moves the capsule with high accuracy, creating shapes which can then be stacked layer upon layer to become truly 3 dimensional creations. Foodini uses state-of-the-art technology, hardware & software, and the power of the internet.

video created by: www.rawmotions.com

Delighting Users

Who uses Foodini? Many people around the world. Foodini is used by restaurants, food service providers, food manufacturers, education and research institutes, nutrition and health companies in over 90 countries. In short: everyone who wants to innovate in the kitchen.

The goal - the mantra:

Foodini is not a machine that seeks to automate the kitchen. It was developed with the intention of encouraging people to eat healthy, homemade ingredients.

Some printed examples:

All these dishes were created and designed by users throgh a complete set of tools, features and operations that Foddini offers by default. Always using natural and fresh ingredients to come up with personal and healthy recipes.

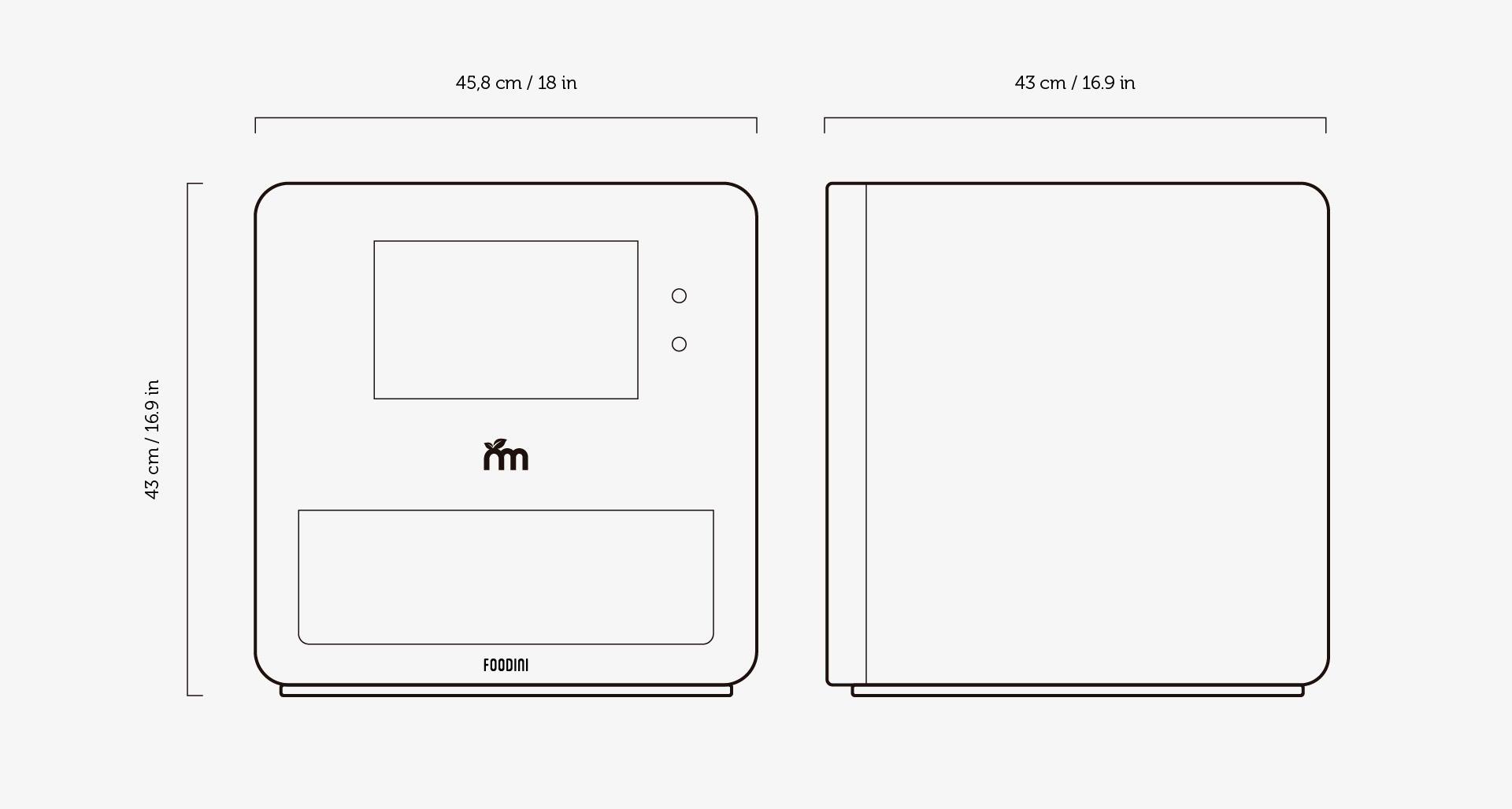

Taking full control through an Onboard Touchscreen

All the interactions with the printer happen via the onboard intuitive touchscreen. Certain specific operations happen by connecting the machine via WiFi through a tablet or laptop.

Making life easier (human computer interactions)

The machine's industrial design and the onboard touchscreen were the starting point.

The frontal position of the touchscreen determined the structure, positioning and view of the entire HCI. The contextual use of the machine was key to understand its usage: on the one hand, the chef is in the kitchen working and cuting vegetables; and on the other hand, they are interacting with the machine through the frontal touchscreen. This requires a divided focused in attention, between what happens on the table, and on the tablet.

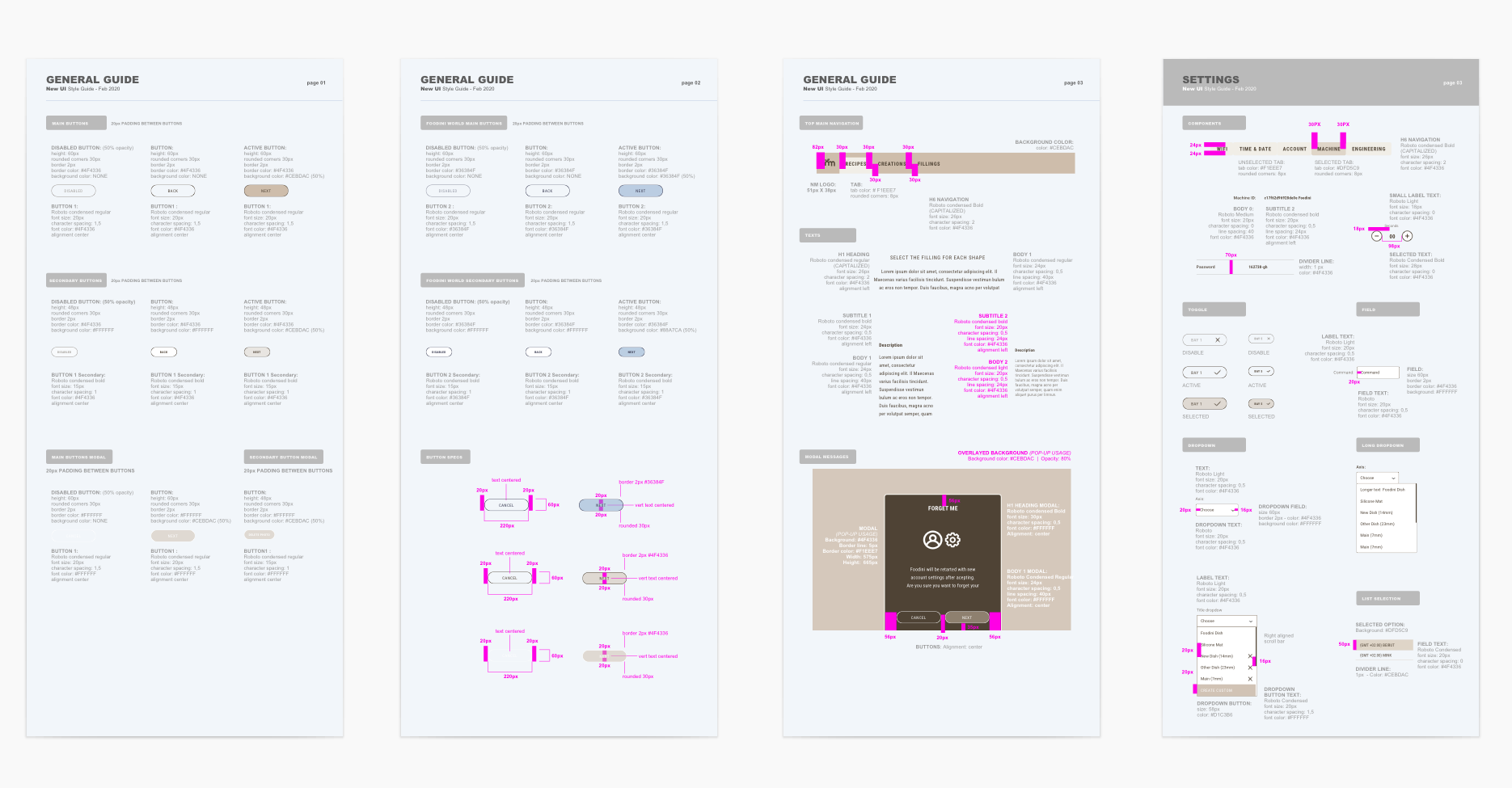

Design System + Workflow + Framework

Wireframes + flowcharts and the visual design were created mainly on Sketch

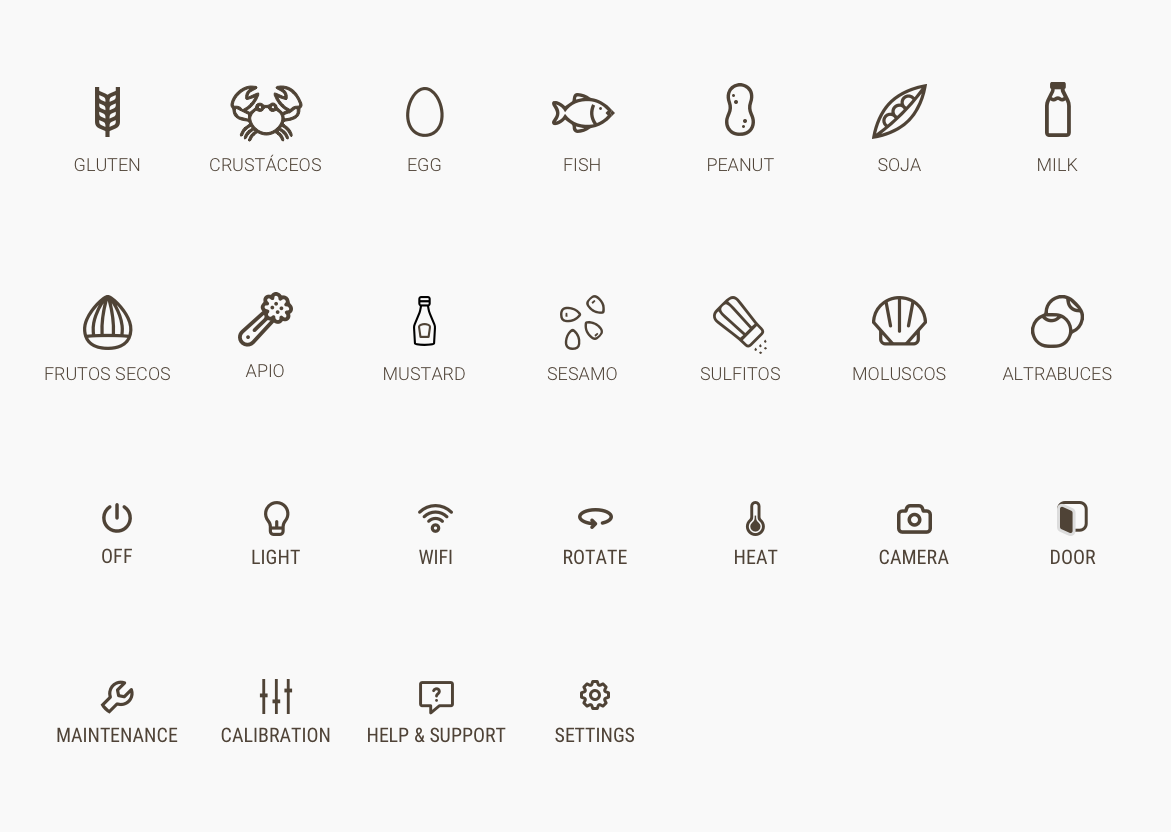

Set of family icons created for different purposes on the printing experience

Developing and implementing the concepts on Flutter

The developer team came up with the idea of moving the framework from React to Flutter. That decision brought many adventages: it's easier to use, features a faster performance over tablet devices, and it's much more flexible and faster to implement. It was the first project I got involved with using this platform and I must admit I was impressed with it.

www.flutter.dev

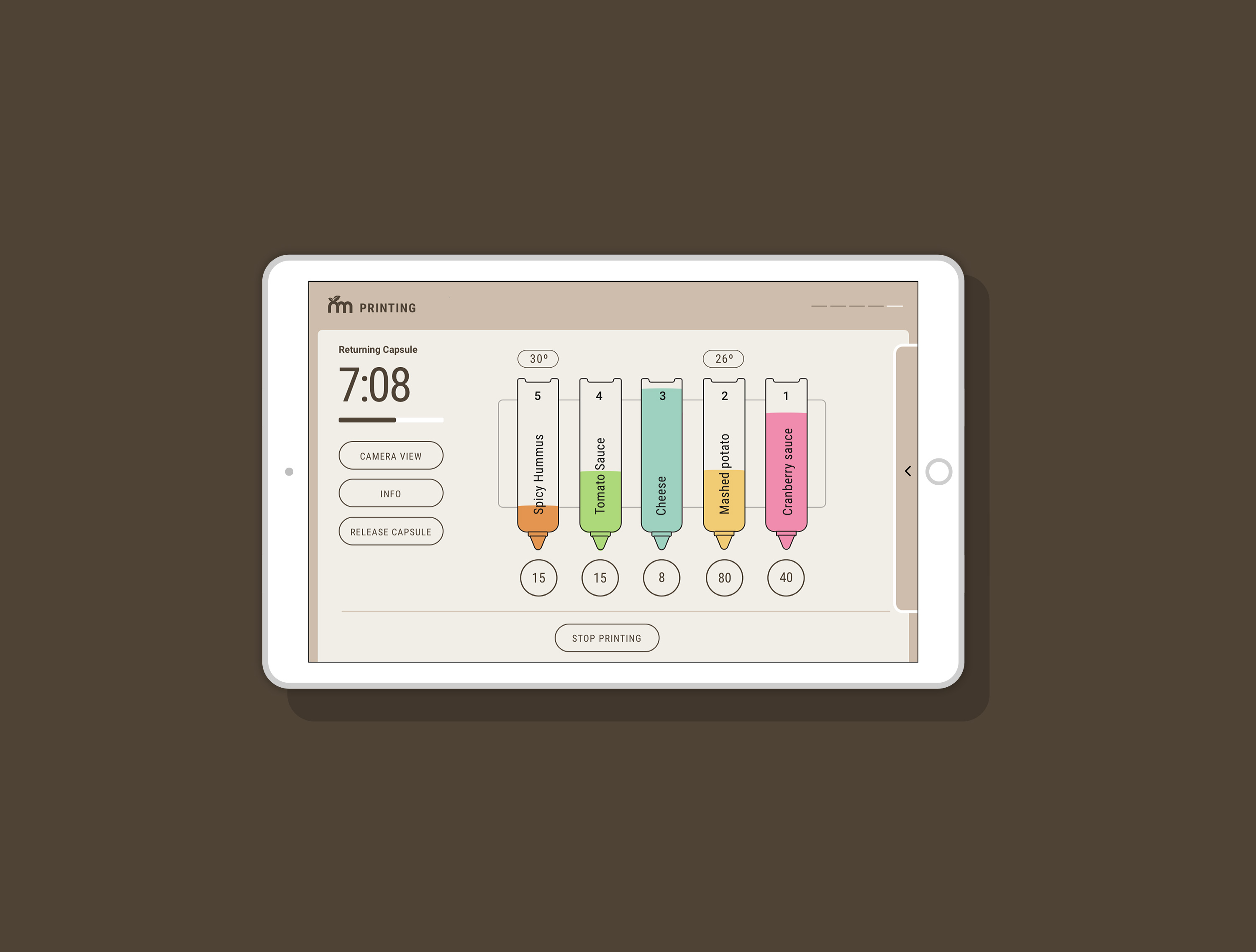

Interfaces speak for themselves

Aesthetics and visual metaphors that represent the complexity of the processes behind in the simplest way possible. A user friendly interface was created by focusing on a minimalist, accesible, and intuitive approach.

FIRST TIME USE: Smooth + brief loading applied on the brand

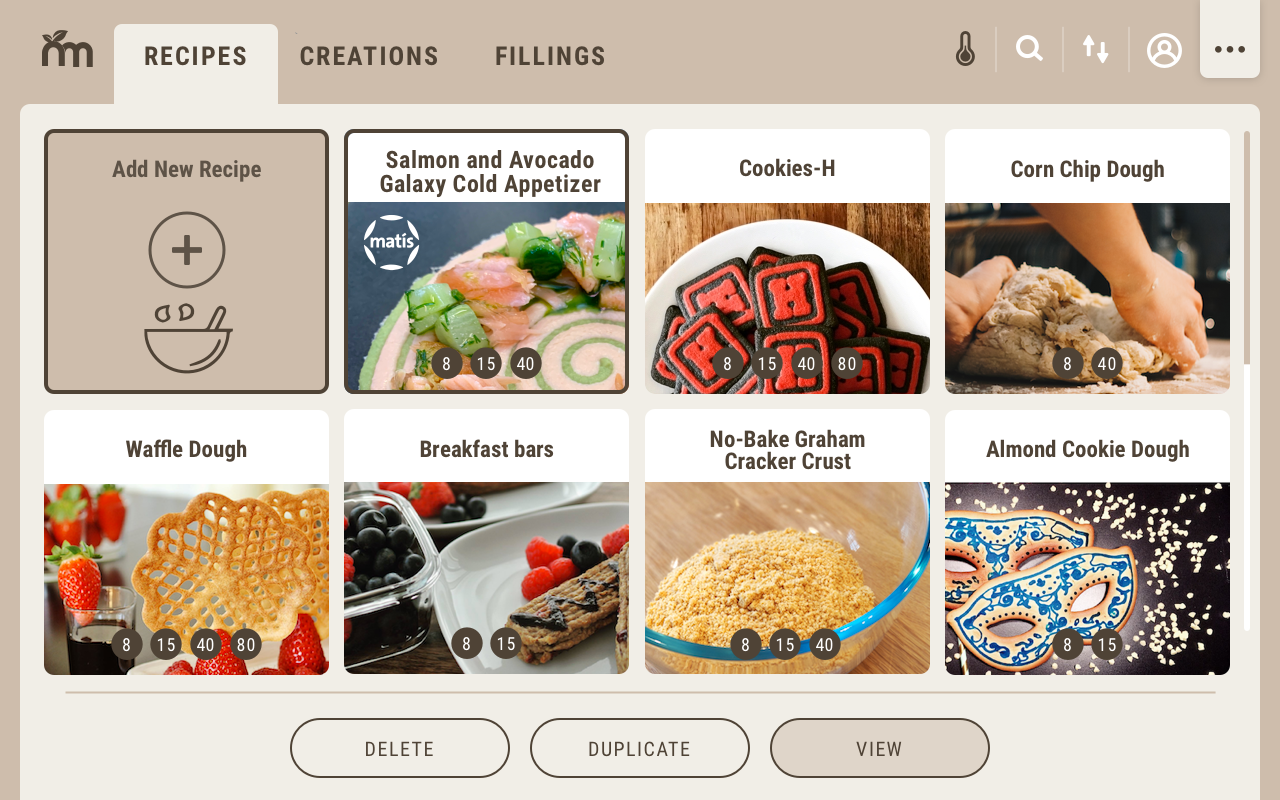

IMAGE USE: only realistic, natural fruit viewed from above

HOME: modular grid where the components are neatly organized

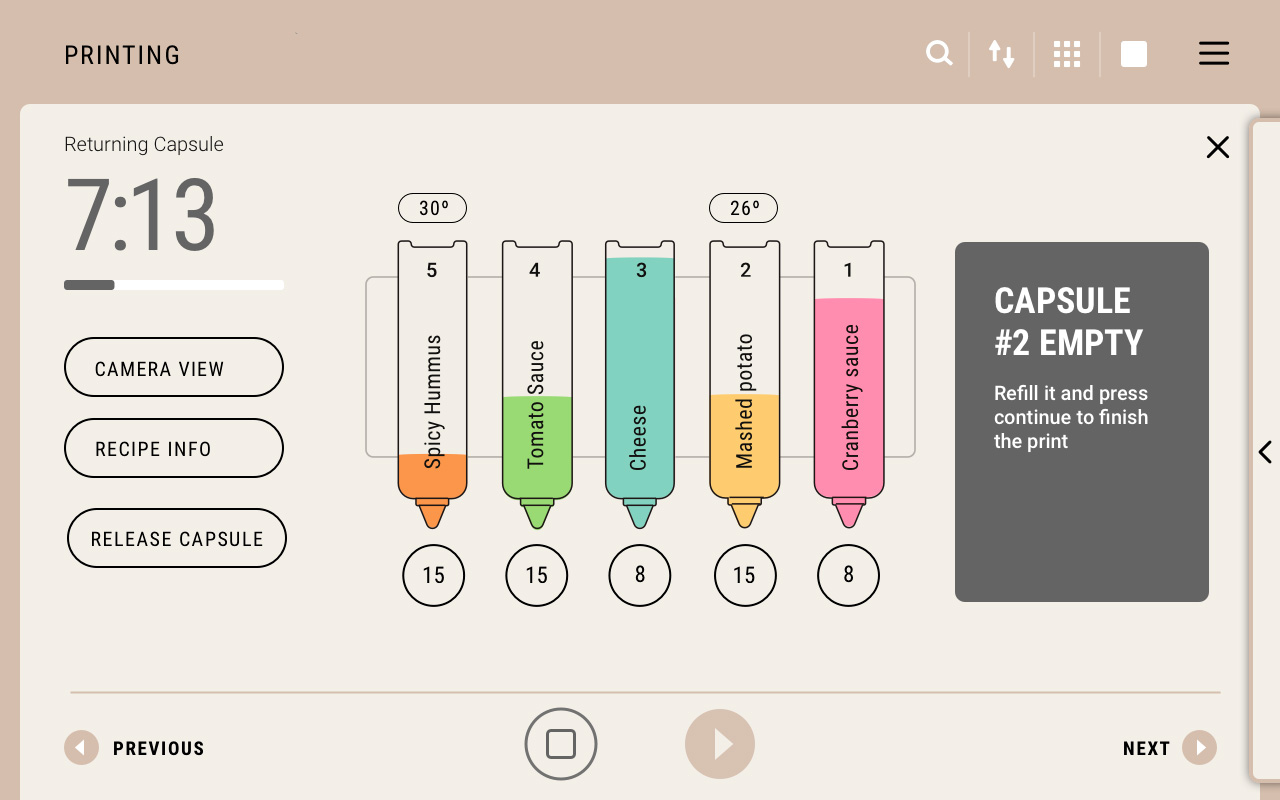

PRINT FLOW: information presented while the printing is happening

PRINT FLOW: information presented while the printing is happening

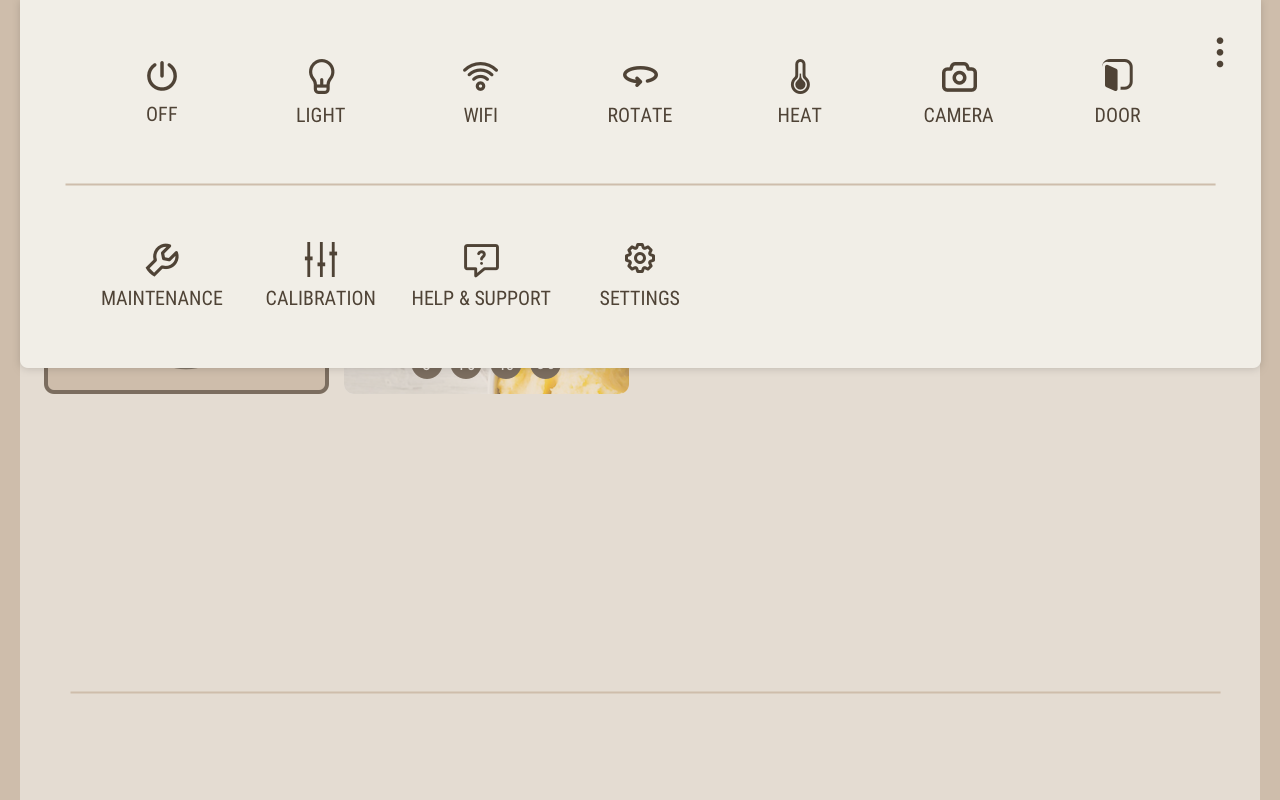

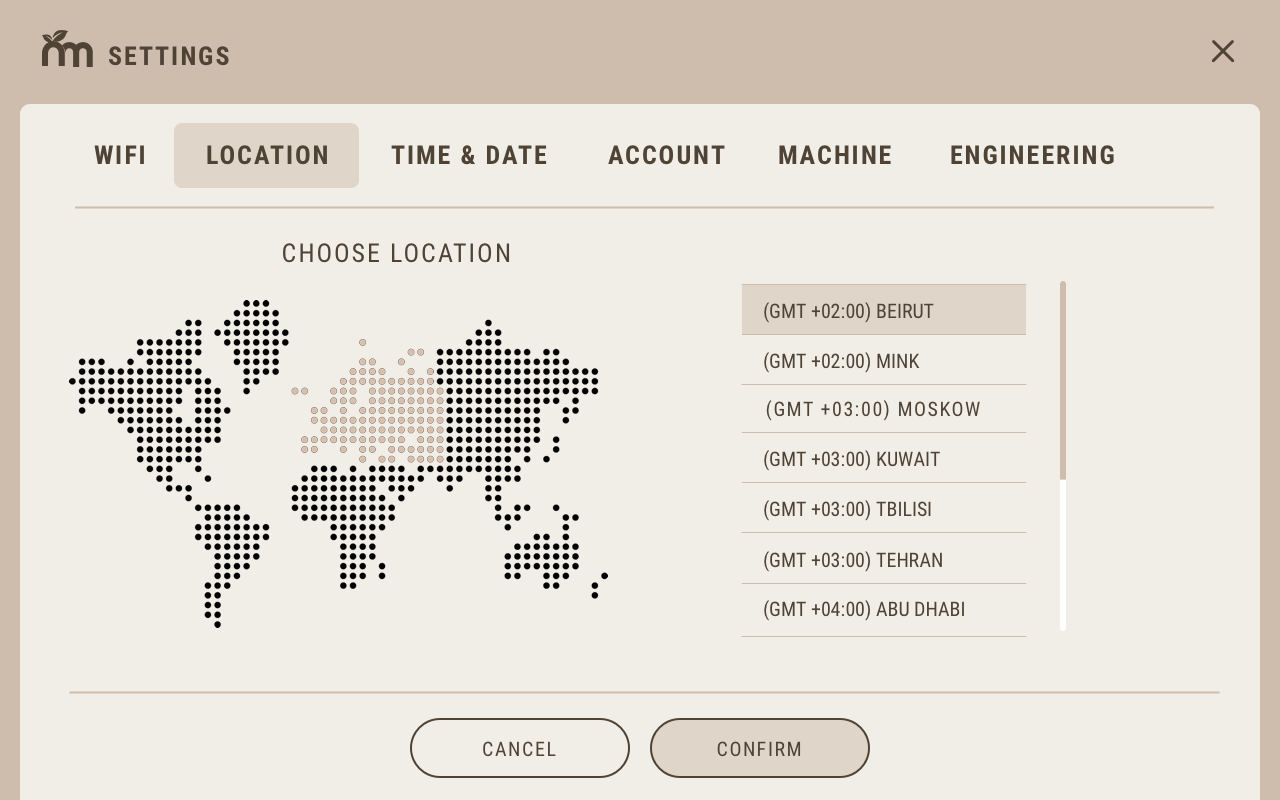

SETTINGS: a secondary hidden menu appears when needed

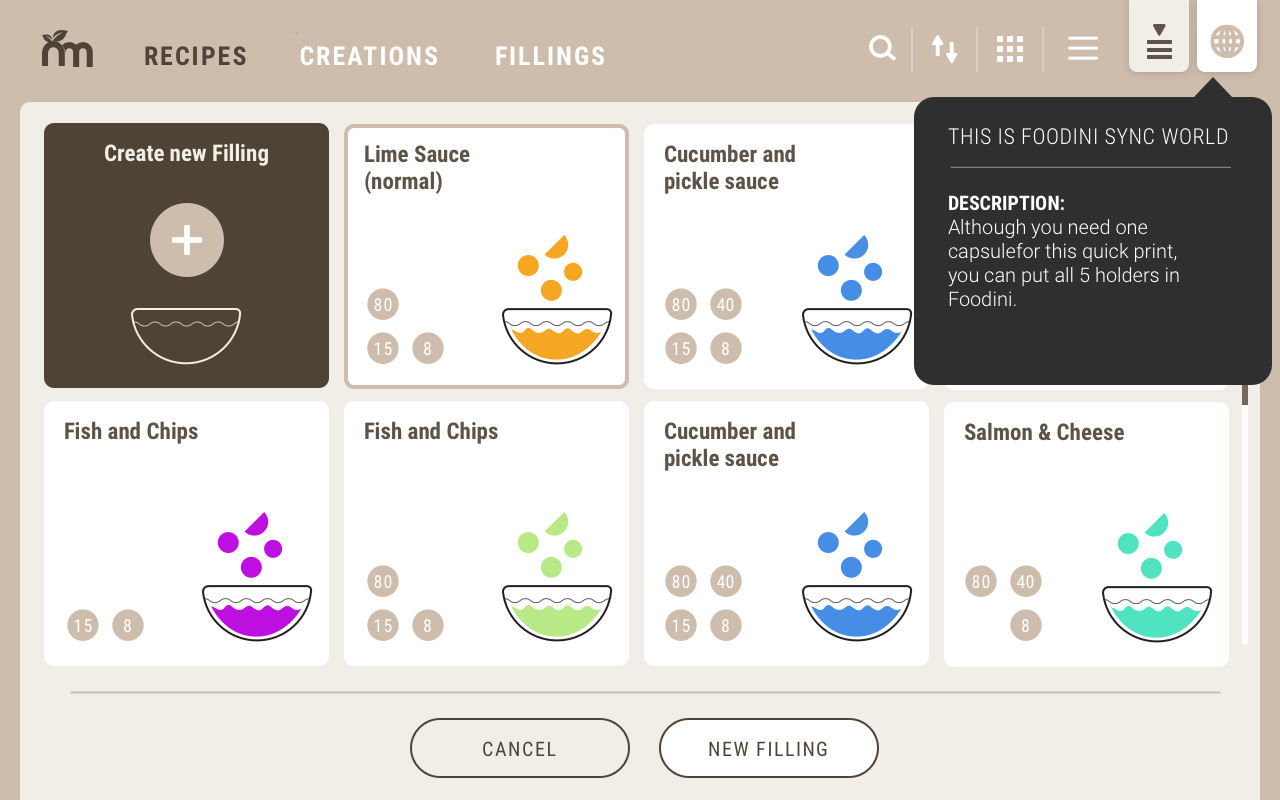

TOOL TIPS: contextual non-intrusive helpful messages

TOOL TIPS: contextual non-intrusive helpful messages

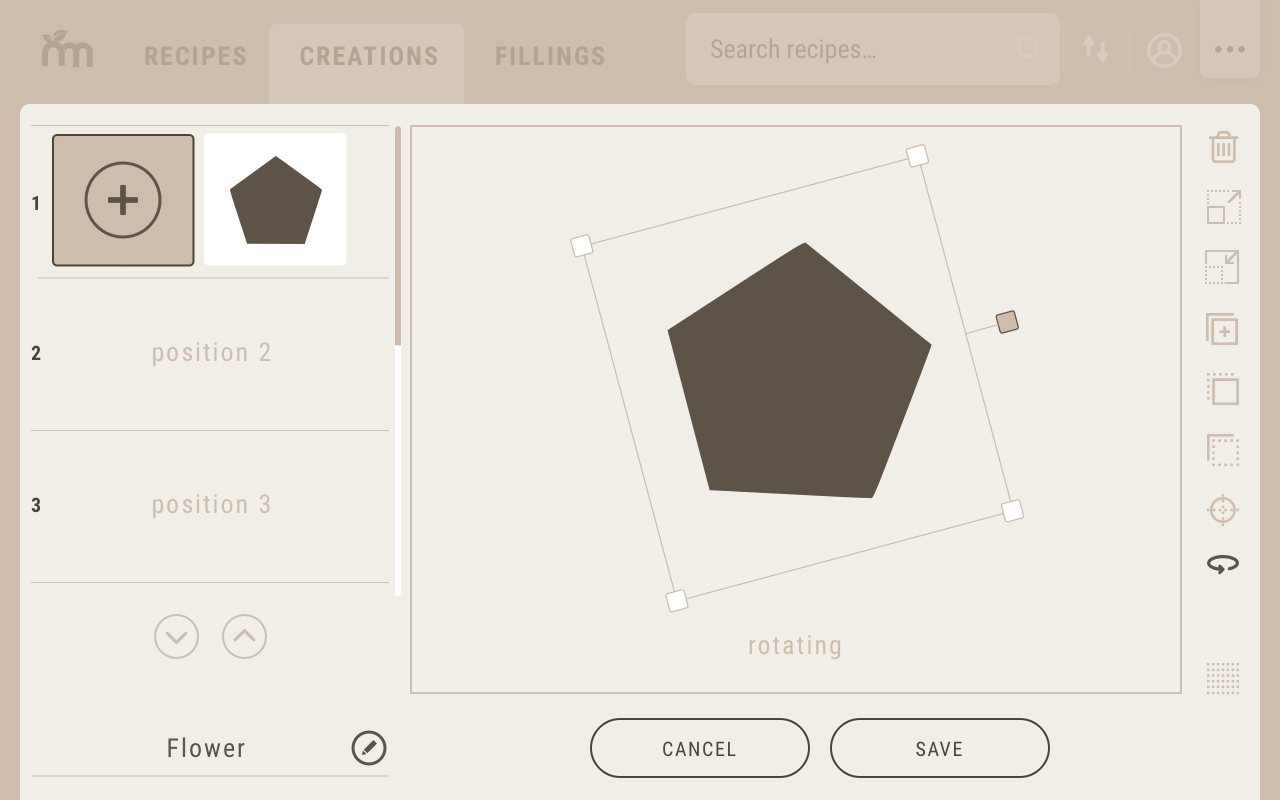

CREATOR: an ecosystem where users can design their recipes

COMPONENTS: prebuilt widgets created on Flutter were recycled

COMPONENTS: prebuilt widgets created on Flutter were recycled

INFOGRAPHICS: engaging approach used for the "boring" tasks

TOOLS: power features designed for customized 3D prints

TOOLS: power features designed for customized 3D prints

The system behind the scenes

During the creative design process, all the components, elements, symbols, and visual ingredients were placed under a comprehensive design system. That way, all future designs could be built by following the rules and universe created on the design system.

To sum up:

Based on my experience, the best way to measure results is always through numbers. better timings, better page views, better performances, etc. No matter the nature of the goals we set out to accomplish for a project, I always measure the results by contrasting the numbers, before and after.

Natural Machines achieves 1.8 million for its 3D food printer

Read the article >

Total Funding Amount: $5.4M

View details >

¿Magic? No, Foodini.

Triggering innovation into Internet of Things: Print as easy as Pie

Some conclusions

Working at Natural Machines was all about innovation, not only on the User Experience and User Interface field, but also on areas like machine learning, laser, 3D printing and many other subjects. I have no doubt that I'll bring the knowledge gained on this project into the next stunning products that I hope to continue developing.An innovative approach requires solid understanding of the current trends

www.naturalmachines.com

Based in Barcelona, New York City and Milan/Turin. 30+ awards. VC backed. Ranked in the top 5% of the FoodTech 500: the Fortune 500 of FoodTech.

Role + Location

UX-UI + Branding Experience Consultant

Barcelona / New York / Milano / Beijing

Skills

- UI User Interface + Visual Design

- Multiplatform Mobile Apps & Multiplatfoms

- Art Direction Art & Creative Direction

- UX User Experience

- pixel perfect GUI Design + Pixel Perfection

- wireframes Wireframing

- Identity Identity & Brand Guidelines

- Typography Typography + Iconography

- web designs Web Design

- Interactive Design + Usability Interactive Design + Usability

- Information Architecture Information Architecture

- Ideation & Conceptual Development Ideation & Conceptual Development

- Creative Suitecase Creative Suitecase Ninja

- Projects Projects & Small Teams Leading